How to Choose Side Stream Filtration for Your Heating System Efficiency

In the quest for enhanced energy efficiency within heating systems, the implementation of side stream filtration for heating system is gaining significant attention. This innovative approach not only targets the reduction of particulate matter and contaminants within the heating loop but also contributes to overall system longevity and performance. With the right filtration system in place, heating efficiency can be optimized, minimizing energy consumption and lowering operational costs.

Choosing the appropriate side stream filtration for heating systems requires a thoughtful evaluation of various factors, including system size, type of contaminants present, and maintenance needs. Understanding these elements is crucial for selecting a filtration system that aligns with your specific heating requirements. This guide aims to provide insights into the selection process, ensuring that homeowners and facility managers can make informed decisions to enhance their heating systems' efficiency and reliability. Through careful consideration and implementation of side stream filtration, significant improvements in heating performance and system sustainability can be achieved.

Understanding Side Stream Filtration and Its Role in Heating Systems

Side stream filtration is an essential component of a heating system that significantly enhances its efficiency and longevity. This process involves circulating a portion of the water from the main system through a filtration device, which removes impurities and particulates. By effectively filtering out these unwanted materials, side stream filtration helps maintain optimal water quality, preventing issues such as scale buildup and corrosion within the heating system.

**Tip:** Regularly check and maintain your side stream filtration system to ensure it functions effectively. Keeping an eye on the filter’s condition can help you catch any potential issues before they escalate, safeguarding your heating system's performance.

Investing in side stream filtration not only improves the efficiency of your heating system but also contributes to energy savings. Clean water allows for better heat transfer, reducing the demand for energy and, consequently, lowering utility bills. Additionally, a well-maintained filtration system prolongs the lifespan of heating equipment, thereby minimizing the need for costly repairs or replacements.

**Tip:** Consider the flow rate of your side stream filtration system when selecting one. Ensure that it aligns with the needs of your heating system to optimize performance and maintain efficiency.

How to Choose Side Stream Filtration for Your Heating System Efficiency

| Parameter | Description | Recommended Value |

|---|---|---|

| Filtration Type | Type of filtration technology used. | Mechanical, Magnetic, Chemical |

| Flow Rate | The rate at which water flows through the filter. | 10-100 GPM |

| Filtration Efficiency | Percentage of particles removed from the water. | 95% or higher |

| Maintenance Frequency | How often the filter needs to be checked or cleaned. | Every 6 months |

| Pressure Drop | The reduction in pressure from inlet to outlet of the filter. | < 5 PSI |

| Material Compatibility | Materials that the filtration system can safely handle. | Copper, Steel, PVC |

Key Benefits of Side Stream Filtration for Energy Efficiency

Side stream filtration plays a crucial role in improving the energy efficiency of heating systems. By filtering out contaminants from the water running through the system, side stream filtration ensures that the primary heating components remain clean and free from deposits. This cleanliness reduces the risk of overheating and system inefficiencies that can arise from dirt and debris buildup. As a result, the heating system operates with greater efficiency, consuming less energy to maintain the desired temperature, which can translate to significant cost savings over time.

Another key benefit of side stream filtration is its positive impact on the longevity of the heating system. By continuously removing particulates, side stream filtration minimizes wear and tear on pumps, valves, and heat exchangers, leading to reduced maintenance needs and downtime. This proactive approach not only extends the life of expensive HVAC components but also enhances system reliability.

As a byproduct, the improved operational efficiency fosters a more sustainable environment, as less energy consumption equates to lower carbon emissions. Emphasizing side stream filtration is not just a choice for immediate efficiency but also a long-term investment in the health of the heating system and environmental well-being.

Factors to Consider When Choosing a Side Stream Filtration System

When selecting a side stream filtration system for your heating system, several crucial factors should be considered to enhance overall efficiency. First, assess the type of contaminants that the system will face. According to a report by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), particulate matter can reduce the efficiency of heating systems by up to 20%. Understanding the specific pollutants present in your environment allows for a more tailored filtration solution, ensuring optimal operation and longevity of your equipment.

Another important aspect is the flow rate of the filtration system. Systems should be designed to accommodate the specific needs of your heating system while maintaining ideal flow rates for proper circulation. According to the National Renewable Energy Laboratory, an improperly sized filter can lead to pressure drops that compromise system performance, potentially increasing energy consumption by 15% or more. Conducting a thorough calculation of your system's requirements is vital to ensure efficiency and prevent excessive wear on the system components.

Tips: Regular maintenance of the filtration system is essential. Clean or replace filters according to the manufacturer's specifications to prevent buildup that can hinder performance. Additionally, consider integrating automatic monitoring to keep track of filter conditions and system efficiency in real-time, which can help preemptively address issues before they escalate.

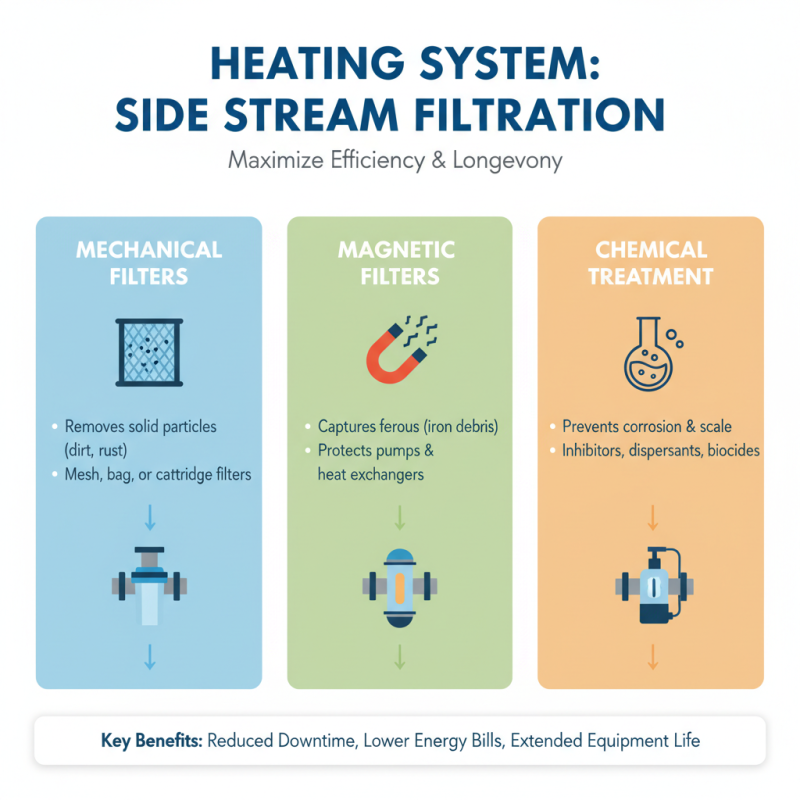

Types of Side Stream Filtration Technologies for Heating Systems

When selecting side stream filtration technologies for your heating system, understanding the various types available is essential for maximizing efficiency and longevity. Side stream filtration works by continuously removing impurities from the heating water, which can lead to corrosion, scale formation, and increased energy consumption. Common types of side stream filtration systems include mechanical filters, magnetic filters, and chemical treatment systems.

Mechanical filters often utilize a combination of strainers and cartridge filters to capture particulate matter, while magnetic filters are designed to attract and remove ferrous particles that conventional filters may miss. According to a report by the National Association of Energy Service Companies (NAESCO), implementing magnetic filtration can reduce maintenance costs by up to 30% over time due to fewer blockages and enhanced system performance. Meanwhile, chemical treatment systems, which inject specific agents to prevent scale and corrosion, can further extend the life of heating components and reduce energy usage, with studies suggesting a potential 15% improvement in efficiency for systems utilizing these treatments regularly.

Choosing the right filtration technology is not only a matter of system compatibility but also involves considering the specific impurities present in your operation. For instance, systems in areas with hard water may benefit significantly from chemical treatments, while those experiencing high levels of particulate contamination may find mechanical or magnetic filters to be more effective. Engaging with a qualified professional to assess the unique needs of your heating system can lead to informed decisions that enhance efficiency and operational reliability.

Maintenance Tips for Optimal Performance of Side Stream Filtration

Maintaining optimal performance of side stream filtration in heating systems is crucial for ensuring system efficiency and longevity. Regular inspections are essential; at least twice a year is recommended. During these checks, look for signs of wear or blockage in the filtration system. A clean filter not only enhances the system's efficiency but also reduces pumping energy. It's important to replace or clean filters as specified by the manufacturer or when pressure drops are observed, indicating a build-up of contaminants.

In addition to routine checks, monitoring the overall water quality within the heating system is vital. Consider using chemical treatment and regular water testing to prevent corrosion and sediment accumulation. Establishing a schedule for maintenance, which includes flushing the system periodically, can further enhance performance.

Keep an eye out for leaks and unusual noises, which may hint at underlying issues that need to be addressed promptly. By staying proactive about maintenance, you can ensure that your side stream filtration system continues to operate at peak efficiency, supporting the overall health of your heating system.

Related Posts

-

7 Compelling Reasons to Choose the Best Side Stream Filtration for Your Heating System

-

Top 10 Benefits of Side Stream Filtration for Heating Systems You Must Know

-

Comprehensive Guide to Microfiltration Membrane Technology: Key Applications and Performance Insights

-

Ultimate Guide to Mastering Cross Flow Filtration Systems for Enhanced Efficiency

-

Innovative Solutions for Optimizing Pulp and Paper Production Efficiency

-

Top 10 Benefits of Hollow Fiber Membrane Filters for Water Purification