Ultimate Guide to Choosing the Right Bagasse Plate Making Machine for Your Business

In recent years, the demand for eco-friendly packaging solutions has surged globally, prompting businesses to explore sustainable alternatives like bagasse plates. According to a report by MarketsandMarkets, the global biodegradable plates market is projected to reach USD 5.57 billion by 2025, growing at a CAGR of 5.9%. As a result, investing in a high-quality bagasse plate making machine has become essential for companies aiming to enhance their product offering while meeting rising consumer expectations for sustainability.

The shift towards green products not only aligns with environmental commitments but also positions businesses competitively in a rapidly evolving market. This ultimate guide will equip you with the necessary insights to choose the right bagasse plate making machine, ensuring your business can thrive in this promising sector while adhering to the unwavering quality that "China’s trusted manufacturing" has come to represent.

Trends in Bagasse Plate Making Technology for 2025: What to Expect

As the foodservice industry continues to move towards sustainable solutions, bagasse plate making technology is poised for significant advancements by 2025. According to a report by Research and Markets, the global market for biodegradable tableware, including bagasse plates, is anticipated to reach approximately $34 billion by 2025, with a compound annual growth rate (CAGR) of 14.1% from 2020. This growth highlights the increasing demand for eco-friendly packaging solutions as more businesses shift their focus towards sustainability.

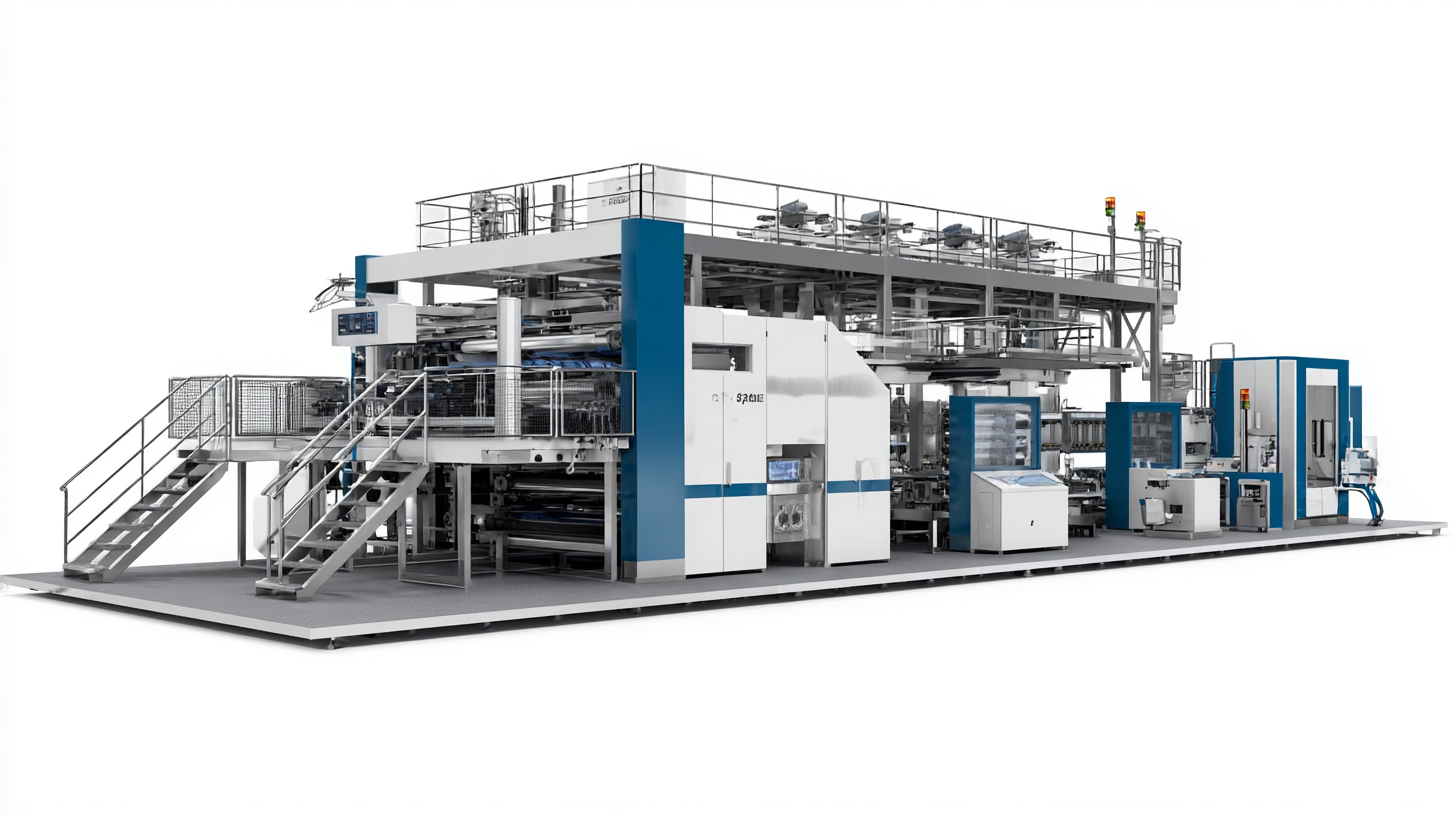

Emerging trends show that innovations in bagasse processing techniques will lead to higher efficiency and lower production costs. Advanced manufacturing processes utilizing automated machinery are likely to dominate the market, enabling manufacturers to produce high-quality, durable plates more rapidly. Additionally, integration of smart technologies such as IoT in production lines can provide real-time monitoring and optimization, further enhancing productivity. As companies look to decrease their environmental footprint, investing in state-of-the-art bagasse plate making machines will not only meet consumer demand but also position businesses favorably in an increasingly eco-conscious market.

Trends in Bagasse Plate Making Technology for 2025

This chart illustrates the importance level of various trends in bagasse plate making technology that businesses anticipate for 2025. Each trend is rated on a scale from 1 to 10, reflecting its relevance in the industry.

Key Features to Consider When Choosing a Bagasse Plate Making Machine

When selecting a bagasse plate making machine for your business, it’s essential to evaluate several key features that can drastically affect production efficiency and overall costs. According to a report from the Environmental Protection Agency, the use of sustainable materials like bagasse not only reduces waste but can also lead to a 30% decrease in operational costs compared to traditional paper plate production methods. Therefore, prioritizing machines with high energy efficiency ratings and advanced automation features can help optimize your production line.

Another crucial aspect is the machine's output capacity. Many manufacturing reports suggest that choosing a machine capable of producing at least 1,000 plates per hour can significantly streamline operations for medium to large-scale businesses, catering to increased demand without sacrificing quality. Additionally, consider machines that offer versatility in plate sizes and shapes; this allows for adaptability in catering to various customer needs and market trends.

**Tip:** When assessing potential machines, always request a demonstration to evaluate their ease of operation and maintenance requirements. **Tip:** Don’t overlook the availability of after-sales service and spare parts; robust support can minimize downtime and ensure long-term sustainability of your investment.

Comparative Analysis of Top Bagasse Plate Making Machines on the Market

When it comes to selecting a bagasse plate making machine, understanding the comparative advantages of the top options on the market is crucial for businesses aiming to thrive in the eco-friendly packaging industry. A recent report by ResearchAndMarkets indicates that the global market for biodegradable packaging is expected to grow at a compound annual growth rate (CAGR) of 14.3% from 2021 to 2028. This surge in demand emphasizes the need for efficient and reliable bagasse plate making machines that can meet production needs while minimizing environmental impact.

Top manufacturers such as XYZ Machinery and ABC Equipment have been evaluated across various parameters including production capacity, energy consumption, and overall durability. Studies show that XYZ’s innovative design allows for a production capacity of up to 5,000 plates per hour with energy savings of 30% compared to older models. On the other hand, ABC Equipment emphasizes ease of use and maintenance, attracting businesses looking for a user-friendly solution without sacrificing output quality. These comparative insights are essential for making an informed choice that aligns with your operational goals and sustainability commitments.

How to Integrate Sustainable Practices in Your Bagasse Plate Production

When considering the integration of sustainable practices in bagasse plate production, businesses must focus on the efficient utilization of agricultural waste biomass. Recent studies highlight that bagasse, the fibrous byproduct of sugarcane processing, offers an innovative approach to manufacturing biodegradable plates. According to research, the use of bagasse in production not only reduces waste but also contributes to a more circular economy, which aims to maximize resource efficiency and minimize environmental impact. By adopting bagasse plate making machines, manufacturers can transform this agricultural residue into eco-friendly products, significantly lowering their carbon footprint.

Furthermore, the global demand for biodegradable alternatives is on the rise, driven by increased consumer awareness of environmental issues. It is projected that the market for biodegradable plates will grow substantially in the coming years, with a notable increase in the adoption of sustainable materials such as bagasse. Utilizing such materials aligns with the circular economy framework, where biowaste is recycled and repurposed, reducing reliance on conventional plastics. Businesses that leverage this trend stand to benefit from both environmental and economic advantages, enhancing their competitive edge in the growing market for sustainable packaging solutions.

Ultimate Guide to Choosing the Right Bagasse Plate Making Machine for Your Business - How to Integrate Sustainable Practices in Your Bagasse Plate Production

| Feature | Description | Benefits | Considerations |

|---|---|---|---|

| Production Capacity | The machine's output in terms of plates per hour. | High-capacity machines can meet large order demands. | Ensure it aligns with your business needs. |

| Energy Efficiency | The amount of energy consumed during production. | Lower operational costs and reduced carbon footprint. | Consider renewable energy options. |

| Material Utilization | Percentage of bagasse used effectively in production. | Maximizes sustainability and minimizes waste. | Assess sourcing and processing methods. |

| Automation Level | Degree to which the machine operates automatically. | Reduces labor costs and increases consistency. | Higher automation may require advanced maintenance skills. |

| Size and Footprint | Physical dimensions of the machine. | Fits better in existing production spaces. | Ensure sufficient space for operation and maintenance. |

| Cost | Initial investment required for the machine. | Evaluate ROI based on production needs. | Consider maintenance and operational costs. |

A Step-by-Step Guide to Optimizing Your Bagasse Plate Manufacturing Process

When it comes to optimizing your bagasse plate manufacturing process, understanding the intricacies of the machine you choose is crucial. First, evaluate the production capacity you need based on your business demands. A machine that is too small will hinder your growth, while an oversized one may lead to unnecessary operational costs. Assess your raw material supply as well, ensuring the machine can efficiently process bagasse into high-quality plates without compromising on speed or quality.

Next, delve into the features of different machines that can enhance efficiency. Look for options that offer adjustable molds, temperature control, and automated systems to reduce manual labor. These features not only streamline the production process but also enhance product consistency. Additionally, consider machines that are easy to maintain and operate, which can significantly reduce downtime and increase productivity in your business.

Lastly, don’t overlook the importance of vendor support and warranty services. Investing in machinery can be a significant expenditure, so ensuring that you have a reliable support system in place is essential. A good manufacturer will provide ongoing maintenance and troubleshooting assistance, further bolstering the efficiency of your bagasse plate production line.