Emerging Trends in Molded Pulp Solutions at the 138th Canton Fair 2025

As the global demand for sustainable packaging solutions escalates, molded pulp has emerged as a leading alternative, gaining traction in various industries. According to a recent report by Smithers Pira, the molded pulp market is projected to grow at a CAGR of over 5% through 2025, driven by the increasing regulatory pressure to reduce plastic usage and the rising consumer preference for eco-friendly products. The 138th Canton Fair 2025 presents a unique opportunity for stakeholders in the molded pulp sector to showcase advancements and innovations that cater to this burgeoning demand.

With its versatility in design and ability to be produced from recycled materials, molded pulp not only aligns with sustainability goals but also offers cost-effective solutions for packaging and product protection, making it a focal point at this influential trade event.

Emerging Technologies in Molded Pulp Manufacturing for Sustainable Packaging

The rising demand for sustainable packaging solutions is driving innovation in molded pulp manufacturing technologies. As global awareness of environmental issues grows, companies are increasingly transitioning from conventional plastics to molded pulp, a renewable and biodegradable alternative. This shift is supported by advancements in the industry, such as the development of manual, semi-automatic, and fully automatic pulp molding machines, which enhance production efficiency and scalability.

Moreover, the molded pulp packaging market is projected to reach USD 5.7 billion by 2027, underscoring its significant growth potential. In Europe, the market share analysis reveals a competitive landscape shaped by emerging trends and consumer preferences toward eco-friendly materials. Molded pulp packaging is not only meeting regulatory standards for sustainability but is also appealing to eco-conscious consumers, providing brands with a way to minimize their environmental footprint. The innovative use of bioplastics derived from renewable natural resources in food packaging further complements this trend, positioning molded pulp solutions as a key player in the ongoing transition to sustainable practices in packaging.

Innovative Design Trends in Molded Pulp Products at the Canton Fair 2025

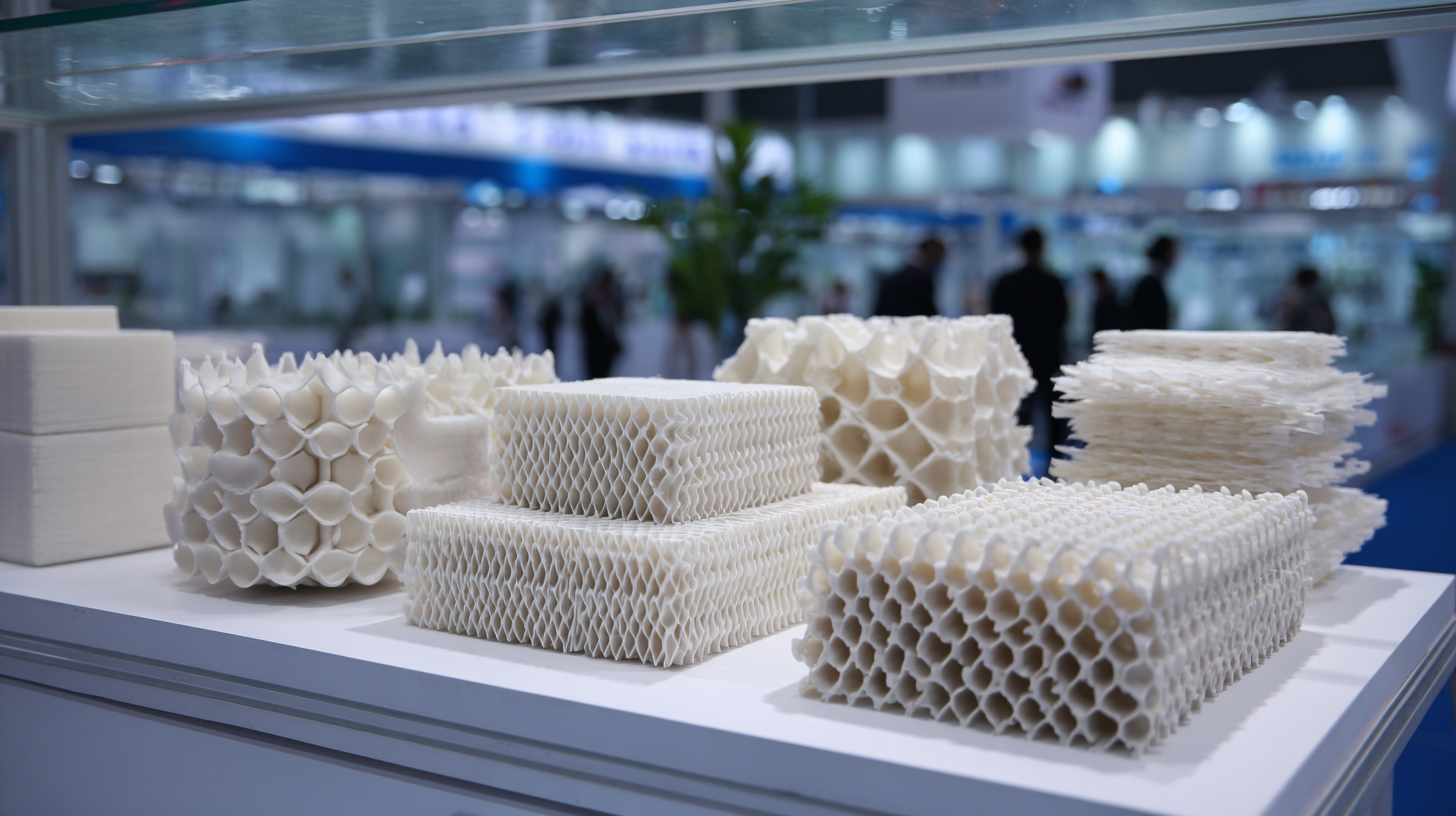

At the 138th Canton Fair in 2025, molded pulp products are set to showcase a range of innovative design trends that emphasize sustainability and functionality. With the ever-increasing demand for eco-friendly packaging solutions, manufacturers are experimenting with unique shapes, textures, and colors that not only attract consumers but also meet environmental standards.

At the 138th Canton Fair in 2025, molded pulp products are set to showcase a range of innovative design trends that emphasize sustainability and functionality. With the ever-increasing demand for eco-friendly packaging solutions, manufacturers are experimenting with unique shapes, textures, and colors that not only attract consumers but also meet environmental standards.

Designers are focusing on creating aesthetically pleasing products that resonate with contemporary tastes while maintaining the biodegradable characteristics of molded pulp.

Additionally, the integration of smart technologies into molded pulp designs is becoming a notable trend. Innovations such as moisture control and temperature sensitivity are being developed to enhance the shelf life of products, particularly in the food industry.

By combining traditional crafting methods with modern technology, producers are able to offer solutions that are both practical and stylish. As these trends unfold during the fair, attendees can expect to see how molded pulp is evolving into a versatile material that caters to a variety of market needs while promoting a greener future.

Market Insights: Demand and Supply of Molded Pulp Solutions in 2025

The demand for molded pulp solutions is set to rise significantly in 2025, driven by increasing consumer awareness of environmental issues and a shift towards sustainable packaging alternatives. As businesses seek biodegradable and compostable options to reduce their carbon footprints, molded pulp products are gaining traction across various industries, including food and beverage, electronics, and cosmetics. This shift is not only influenced by regulatory pressures but also by a growing trend among consumers who prefer eco-friendly packaging, prompting manufacturers to rapidly innovate and meet the changing demands.

On the supply side, advancements in manufacturing technologies and raw material sourcing are paving the way for enhanced production efficiencies and cost-effectiveness. The 138th Canton Fair in 2025 will showcase a plethora of innovations in molded pulp solutions, allowing suppliers to connect with potential clients and explore new market opportunities. As the market evolves, collaborations between material suppliers, manufacturers, and retailers will be essential to navigate challenges in scaling production and ensuring consistent quality, ultimately shaping the future landscape of molded pulp solutions in the market.

Emerging Trends in Molded Pulp Solutions - Market Insights 2025

The chart above illustrates the projected demand and supply of molded pulp solutions across various global regions in 2025. The data indicates a higher demand in Asia, while supply is significantly lower, highlighting potential market opportunities for growth and investment in the molded pulp sector.

Case Studies: Successful Applications of Molded Pulp in Various Industries

At the 138th Canton Fair in 2025, molded pulp solutions are gaining significant attention, particularly for their innovative applications across various industries. One remarkable case study comes from the electronics sector, where a leading company adopted molded pulp packaging for its delicate components. The biodegradable nature of molded pulp not only reduced environmental impact but also provided superior cushioning during transit, minimizing damage and enhancing customer satisfaction.

Another compelling example is found in the food service industry, where a restaurant chain has successfully implemented molded pulp trays for their takeaway meals. These trays offer a sustainable alternative to traditional plastic packaging while maintaining hygiene and presentation. The ability to mass-produce these trays has allowed the chain to scale sustainably, proving that eco-friendly practices can indeed coexist with business growth. As more companies explore molded pulp solutions, it is clear that this trend is reshaping industry standards for sustainability and innovation.

Emerging Trends in Molded Pulp Solutions at the 138th Canton Fair 2025

| Industry | Application | Benefits | Sustainability Impact |

|---|---|---|---|

| Food Packaging | Egg cartons, fruit trays | Biodegradable, lightweight | Reduces plastic waste |

| Electronics | Protective packaging for gadgets | Shock absorbent, customizable | Promotes circular economy |

| Cosmetics | Product trays, gift boxes | Aesthetic appeal, protective | Encourages eco-friendly branding |

| Agriculture | Seedling trays | Promotes plant growth | Reduces chemical use |

| Retail | Point of purchase displays | Eye-catching, eco-friendly | Supports sustainable shopping |

Future Prospects: The Role of Molded Pulp in Global Sustainability Initiatives

The growing emphasis on sustainability has propelled molded pulp solutions into the spotlight, particularly at events such as the 138th Canton Fair in 2025. Molded pulp, made from recycled paper and designed to replace plastic packaging, is increasingly recognized for its role in global sustainability initiatives. According to a recent report by MarketsandMarkets, the molded pulp packaging market is expected to reach USD 3.01 billion by 2025, growing at a CAGR of 7.8%. This growth highlights the demand for eco-friendly packaging alternatives as companies strive to meet both consumer expectations and regulatory requirements aimed at reducing plastic waste.

One of the key advantages of molded pulp is its biodegradability and recyclability, significantly contributing to circular economy efforts. A study from Smithers Pira found that nearly 75% of consumers are willing to pay more for products packaged sustainably. This trend not only positions molded pulp as a viable alternative to traditional packaging but also aligns with the broader objectives of reducing the environmental impact of packaging waste.

Tip 1: When considering molded pulp for packaging, ensure that your supplier uses post-consumer recycled materials to maximize sustainability benefits.

Tip 2: Engage your customers by highlighting your commitment to sustainability through eco-friendly packaging, as transparency can enhance brand loyalty.

Related Posts

-

What is the Future of Filter Technology in Environmental Sustainability

-

Unwavering Quality from Trusted Chinese Manufacturers Featuring the Best Vacuum Filtration Systems

-

Exploring Alternatives to Best Microfiltration Membrane Technology for Enhanced Water Purification

-

Ultimate Guide to Navigating Challenges in the Paper Industry: Best Practices and Solutions

-

7 Reasons Why Bag Filter Systems are Essential for Reducing Industrial Emissions

-

How Filter Technology Reduces Waterborne Contaminants by 99.9% in Industrial Applications