2025 How to Optimize Pulp and Paper Production for Sustainability and Profitability

In an era where environmental sustainability and economic viability are paramount, the pulp and paper industry stands at a critical crossroads. With increasing global demand for sustainable practices, optimizing production processes has never been more important. This paper explores innovative strategies and best practices aimed at enhancing both the sustainability and profitability of pulp and paper operations. As companies strive to reduce their environmental footprint while maintaining competitive advantage, a comprehensive understanding of sustainable methods in pulp and paper production becomes essential.

The integration of advanced technologies and sustainable practices not only aids in minimizing waste and reducing emissions but also fosters greater resource efficiency. It is vital for industry stakeholders to recognize the potential benefits of adopting such practices, as they not only align with regulatory demands and consumer preferences but also lead to long-term profitability. This article delves into the various approaches that can be utilized to optimize pulp and paper production, highlighting successful case studies and emerging trends in the sector. Through strategic innovations, the pulp and paper industry can pave the way for a more sustainable and profitable future.

Current Sustainability Challenges in Pulp and Paper Production

The pulp and paper industry faces significant sustainability challenges that impact both its environmental footprint and economic viability. One of the primary issues is the reliance on wood fiber, which often leads to deforestation and loss of biodiversity. The escalating demand for paper products exacerbates this problem, prompting manufacturers to source raw materials in a way that may compromise sustainable forest management practices. As production ramps up, the associated carbon emissions and wastewater arise as critical concerns, highlighting the need for a comprehensive approach to mitigate these environmental impacts.

In addition to resource use, energy consumption remains a crucial sustainability challenge in the pulp and paper sector. The industry is traditionally energy-intensive, primarily depending on fossil fuels, which contribute to greenhouse gas emissions. Transitioning to renewable energy sources and implementing energy-efficient technologies are essential steps to improve sustainability. Moreover, introducing closed-loop systems can significantly reduce waste and emissions, ultimately enhancing both environmental performance and profitability. As companies seek to navigate these challenges, fostering a culture of innovation and adopting sustainable practices will be vital for securing the long-term health of the industry.

Innovative Technologies for Enhanced Resource Efficiency

The pulp and paper industry faces significant challenges in balancing sustainability with economic viability. Innovative technologies play a crucial role in enhancing resource efficiency and minimizing environmental impact. One such advancement is the integration of digitalization and automation in manufacturing processes. By employing real-time data analytics and IoT devices, mills can monitor operational efficiency, reduce waste, and optimize energy consumption. This approach not only conserves resources but also improves productivity, leading to a more sustainable production model.

Another promising innovation is the development of biodegradable and sustainable raw materials. Research into alternative fibers, such as agricultural residues and recycled materials, helps reduce reliance on traditional wood sources. Additionally, advancements in bioprocessing technologies enable the extraction of lignin and other byproducts, transforming waste materials into valuable resources. By embracing these eco-friendly practices, the industry can not only support environmental sustainability but also create new revenue streams and enhance overall profitability.

Implementing Circular Economy Practices in Pulp and Paper Industries

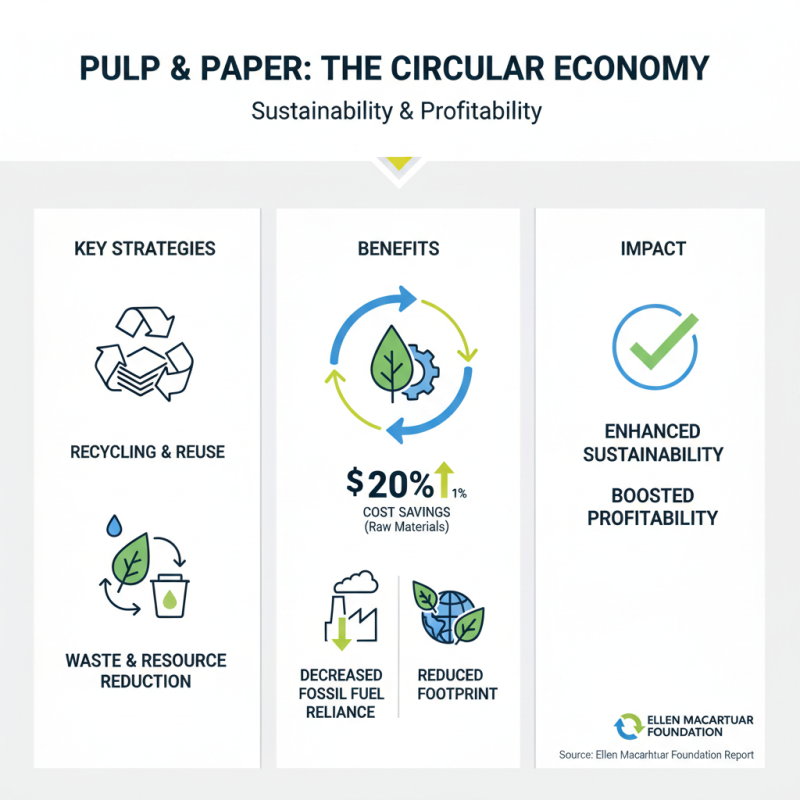

The implementation of circular economy practices in the pulp and paper industry is critical for enhancing sustainability while boosting profitability. According to a report by the Ellen MacArthur Foundation, transitioning to a circular economy could reduce raw material costs by around 20% for various sectors, including pulp and paper. By adopting strategies such as recycling and reusing materials, manufacturers can significantly lower waste generation and resource consumption while optimizing operational efficiency. The industry's fossil fuel reliance can also diminish as part of this circular framework, aligning with global sustainability targets and reducing carbon footprints.

Integrating sustainable practices not only enhances environmental stewardship but also meets the growing consumer demand for eco-friendly products. The World Bank estimates that the global paper market is valued at around $500 billion, and within this framework, industries can realize substantial reductions in landfill waste—up to 50% by maximizing the use of recycled fibers. Furthermore, adopting technologies that monitor material flow can improve decision-making and resource management. As companies shift towards closed-loop systems, profitability can be enhanced through reduced costs of raw materials and increased operational resilience, positioning the industry favorably in an increasingly eco-conscious market.

Strategies for Reducing Waste and Emissions during Production

In the quest for more sustainable pulp and paper production, focusing on strategies that reduce waste and emissions is essential. According to the American Forest & Paper Association (AF&PA), the industry has set ambitious goals to reduce greenhouse gas emissions by 20% and improve energy efficiency by 25% by 2025. Implementing advanced technologies such as closed-loop water systems can significantly lower water usage and diminish pollutants released into waterways, which aligns with these sustainability targets. Moreover, the adoption of renewable energy sources like biomass and solar energy could further reduce carbon footprints, providing an opportunity for mills to operate more efficiently while minimizing environmental impacts.

Another effective approach to minimizing waste is through circular economy practices. The World Economic Forum reports that circular solutions could reduce global resource consumption by up to 28% by 2030, representing substantial cost savings. For pulp and paper producers, embracing recycling initiatives not only conserves raw materials but also ensures that end-of-life paper products are efficiently repurposed. Establishing collaborations with local recycling firms and optimizing the supply chain can contribute significantly to waste reduction. With a growing consumer preference for sustainable products, focusing on these strategies will not only enhance profitability but also reinforce the industry's commitment to environmentally responsible practices.

Measuring Profitability through Sustainable Practices in Pulp and Paper

The pulp and paper industry is faced with the pressing challenge of balancing sustainability and profitability. Moving towards sustainable practices is not merely an ethical choice but a strategic one that can lead to increased profitability. Companies are increasingly recognizing that integrating environmentally friendly processes can reduce costs, enhance brand reputation, and drive operational efficiencies. This necessitates a thorough assessment of current practices and a commitment to continuous improvement.

Tips for measuring profitability through sustainable practices include regularly analyzing resource consumption and waste generation. Implementing a comprehensive monitoring system can provide insights into areas where energy efficiency can be improved, thereby cutting costs. Additionally, investing in renewable energy sources, such as biomass or solar, can significantly reduce long-term operational costs.

Another crucial aspect is fostering a culture of sustainability within the organization. Engaging employees in sustainability initiatives not only empowers them but also leads to innovative ideas for waste reduction and resource optimization. Encourage team collaboration by setting sustainability goals and rewarding contributions that enhance environmentally-friendly practices. This holistic approach can ultimately transform sustainability from a cost center into a profit-driven endeavor, driving the long-term success of pulp and paper production.

2025 How to Optimize Pulp and Paper Production for Sustainability and Profitability

| Sustainable Practice | Impact on Production Cost (%) | Impact on Yield (%) | Reduction in Waste (%) | Return on Investment (ROI) |

|---|---|---|---|---|

| Energy Recovery Systems | 15% | 10% | 20% | 25% |

| Recycling and Reusing Water | 10% | 8% | 30% | 22% |

| Sustainable Sourcing of Raw Materials | 12% | 15% | 25% | 18% |

| Process Optimization Technologies | 8% | 12% | 18% | 20% |

| Employee Training and Engagement | 5% | 5% | 10% | 15% |

Related Posts

-

Top 10 Innovations Transforming the Pulp and Paper Industry for a Sustainable Future

-

Innovative Solutions for Optimizing Pulp and Paper Production Efficiency

-

Emerging Trends in Best Pulp Industries to Watch for Global Buyers in 2025

-

Revolutionizing Clean Air: How Industrial Air Scrubber Systems Enhance Workplace Safety and Efficiency

-

What is the Future of Filter Technology in Environmental Sustainability

-

Exploring the Versatility of Wood Pulp Paper: Eco-Friendly Innovations and Future Trends